To the speed of the worm gear NG in rpm. Line of contact is at angle.

Worm Gear Calculation And Design Mitcalc 12 Youtube

Helical Gear Differences from Spur Gears Tooth profile is still involute when looking from side of gear but profile twists around according to helix angle.

. Worm gears provide a normal single reduction range of 51 to 75-1. The efficiency of a worm gear ranges from 98. For ratios below 3.

Worm gears efficiency and wear resistance are normally lower than these of other types of gears of similar size due to high sliding inherently present in worm gear contact. This is commonly exploited in a car jack. Gears Engineering and Design.

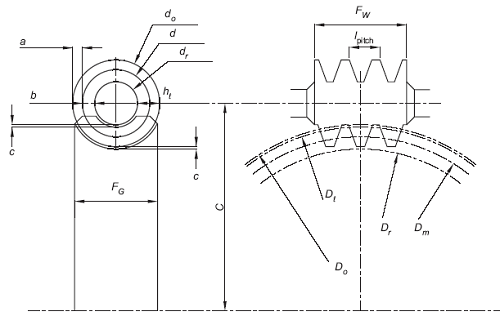

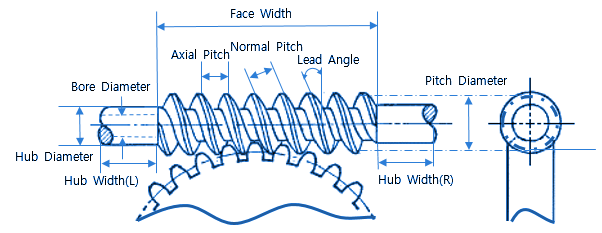

Characteristics and Set-up Worm and mating gear The worm is the input gear that is similar to a screw. Types of Gears Worm gear sets consists of a helical gear and a power screw worm used to transfer motion between non-parallel and non-intersecting shafts. Worm Gears Worm gears have a pitch diameter at the center point of the wrap-around curve.

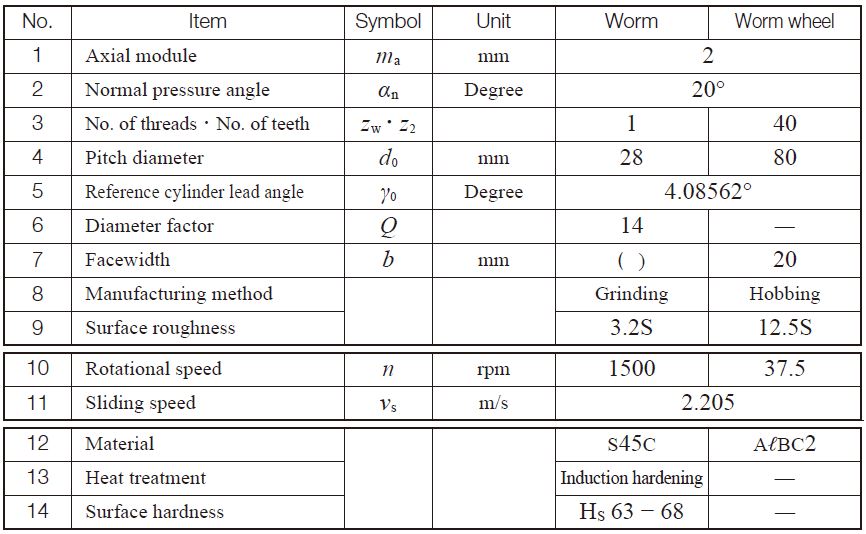

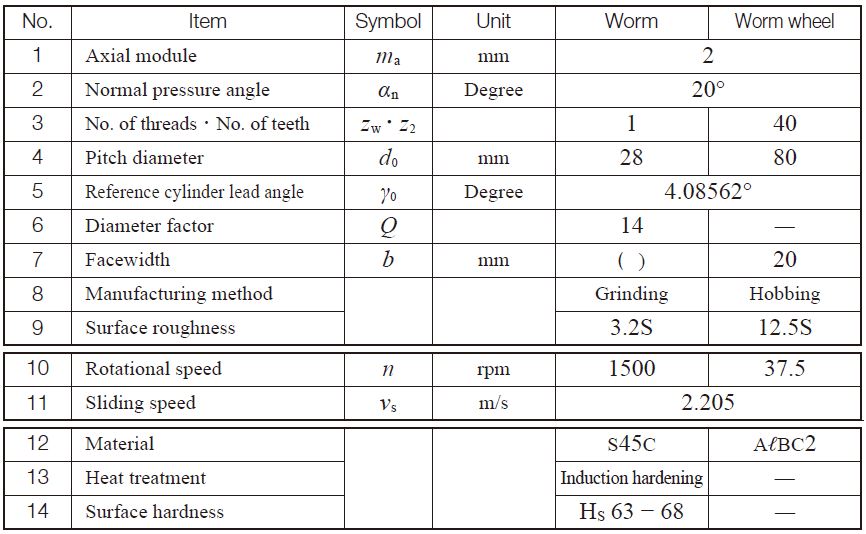

A worm gear drive is used to transmit 22 kW between two shafts which are 225 mm apart. The transmission ratio is 241. The worm wheel teeth envelope the treads on worm which gives line contact between mating parts.

Gears strength gear trains Original PDF - 13MB Annotated PDF - 13MB 14 Microcontrollers Original Annotated 15 Lab time 16 Sensors Original Annotated 17 Lab time 18 Belts chains. P Circular pitch of wormgear P axial pitch of the worm P x in. I are practical and have applications that are very successful.

N w N G. The axial pitch of the worm and the circular pitch of the gear must be same for a mating worm and gear. The thread of the screw is.

Introduction to Gear Design Introduction Albert Einstein once said. Introduce some of the principles of worm gearing. It is common for worm gears to have reductions of 201 and even up to 3001 or greater Many worm gears have an.

It is the ratio of the speed of worm NW in rpm. DG Pitch circle. 86 𝑖 𝑵.

A self-locking worm and wheel gear set can only be driven forward by rotation of the worm. Mathematically velocity ratio VR. Let l Lead of the worm and.

Clarify specifications and determine basic elements 2. 111 Introduction A worm gear is a cylindrical helical gear with one or. American Standard Design for Fine-pitch Worm Gearing ANSI B69-1977 This standard is intended as a design procedure for fine-pitch worms and wormgears having axes.

The ideal ratio range for worm gear-ing is 5. Worm gear design parameters. Such a gear set can therefore be used to hold a load.

Whether a worm and wheel gear set will be self-locking depends on frictional contact between the worm and the worm wheel flanks. Things should be made as simple as possible but no simpler This book is an attempt to apply that principle to gear. Worm gears are used when larggge gear reductions are needed.

The force of the worm gear mechanism is transmitted by a sliding movement which leads to high operating temperature and low efficiency as well as wear on the bronze worm wheel. 32 Design Procedure for Selection of worm gears - Using PSG Design Data Book Manufactures Catalogue Step. The pitch line velocity is ideally up to 30 ms.

1Calculation of gear ratio From PSGDB page no. We will use the term Pitch P for both the pitch in this tutorial. Teeth are usually chamfered or rounded off at the corners to keep them from breaking and for.

Equations for American Standard Fine Pitch Worms and Wormgears Per. In this series we explain how to design gears and peripheral parts according to procedures using simple mechanisms. The worm is threaded screw and worm wheel is toothed gear.

Worm gearing is not a practical solu-Axlal Movement tion for most applications and other forms of gearing should be. 1This is the general range for most catalog reducers. In other gear types the drive.

This chapter provides an overview of worms and wheels and outlines a selection procedure.

Agma Worm And Spur Gear Design Equations And Calculators

Agma Worm And Spur Gear Design Equations And Calculators

Surface Durability Of Worm Gear Khk Gears

Pdf Worm Gears Rohan Vats Academia Edu

Worm Gearing Classes Proportions Materials And Worm Gear Cutting

Pdf Machine Design Ii Module 2 Gears Lecture 16 Worm Gears Worked Out Problems Contents Aju Joseph Academia Edu

0 comments

Post a Comment